Ultrasonic Inspection

Digital Flaw Detector :

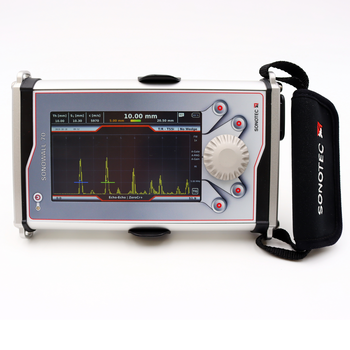

SONOSCREEN ST10

The SONOSCREEN ST10 can be used for all conventional ultrasonic tests such as weld inspections, wall thickness measurements and the detection of discontinuities, which includes invisible cracks, inclusions, voids and other discontinuities in metals, plastics, ceramics and composites.

- Great Performance and intuitive menu navigation

- High performing square wave transmitter

- High-resolution 8″ graphic display, 16:9 format

- 5 ns resolution over the entire measurement range robust aluminum housing, IP66 certified

- 2 GB internal memory for storing up to 60.000 A-scans plus device configuration

- External data storage on USB flash drive

- Weld seam testing

- Casting and forging inspection

- Sheet metal testing

- Plastic and composite testing

- Wheel and axle testing

- Wall thickness measurement

Wall Thickness Measurement

Wall thickness measurement as part of non-destructive testing is one of the most common uses of ultrasonic technologies. In addition to the classic measurement of wall thickness as part of quality control, our precise wall thickness measurement devices can also be used to detect damage caused by erosion and corrosion on, for example, ships, storage tanks, pipelines and cranes. We have a variety of versions of our devices for all types of applications.

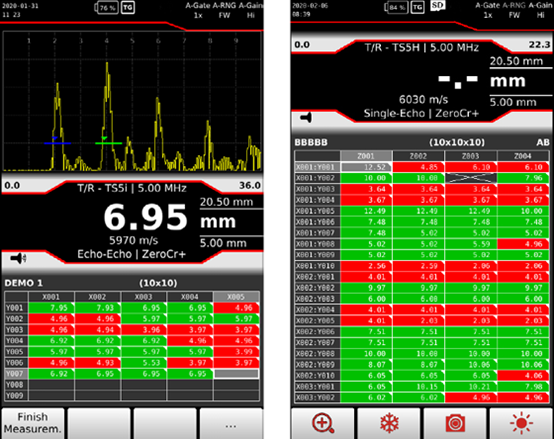

SONOWALL 70

The SONOWALL 70 thickness gauge is perfectly suited for various ultrasonic thickness applications. The robust aluminium casing with IP 67, a light weight of only 990g and high-resolution anti-glare 5-inch graphic display make the SONOWALL 70 the ideal thickness gage in harsh test environments.

In addition to high performance, the focus during the development for SONOWALL 70 thickness gage was on intuitive handling and clear display of measurement results. An intuitive user interface, clearly structured menu, and the presentation of all menu items in full text simplify and accelerate the set-up and operation of the device, and reduce the risk of incorrect settings.

All relevant measurement values and device settings such as wall thickness, A- or B-Scan, and individually adjustable test parameters are apparent at a glance on the large display screen (800×489). Thanks to the innovative flip-screen technology, the device can be used with either hand for convenient working.

SONO-ID INTELLIGENT PROBE RECOGNITION :

Intelligent probe identification

SONOWALL 70 is the first thickness gage in the market with intelligence probe identification. The extended probe management allows probe-specific information, such as DAC-curves, delay lines and serial numbers, to be saved directly in the probe.

ADVANTAGES

- High performance & compact design

- Flip-screen-feature simplifies usage

- Robust aluminum casing, IP 67

For various thickness applications

- Corrosion testing – NEW SONOGRID software

- Through-coat testing

- Precision measurement

SONOGRID Corrosion Management Software

Corrosion and erosion defects are among the most common safety risks and reasons for production break downs in industrial environments such as refineries, pipeline networks, chemical plants, offshore platforms, storage tanks, etc. In order to maintain assets and to avoid hazards, ultrasonic thickness measurements are typically recorded frequently at pre-defined points creating a virtual grid on the surface of the test object.

To help collect, organize and report readings efficiently, the SONOWALL 70 ultrasonic thickness gage can be equipped with the SONOGRID corrosion management software.

STRUCTURED DATA COLLECTION

Matrix creation Linear, 2D and 3D for efficient data collection and test path visualization

Color coding Visual indication of material condition and exceeded tolerances

Live comparison Each point can be compared to previously logged point to estimate corrosion rates

SONOWALL 70

SONOWALL 50

SONOWALL 60

SONOGRID Corrosion Management

High Temperature Corrosion Kit

Ultrasonic Probes

We offer wide range of transducers for various applications such as Flaw Detection, Thickness Gauging & Material Research.

Our Standard range includes:

- Contact normal beam transducers

- Dual element transducers

- Angle beam transducers

- Immersion transducers (Focused / Non-focused)

- Transducers with replaceable delay line / Angle Wedges

Transducers are manufactured in subminiature, miniature, normal & large crystal size, to suit the component shape & test requirements. A wide range of frequency & size of crystal is available. Special custom designed transducers are also manufactured to suit specific test requirements, with modified case designs, connectors, special wedges, etc.

Our Special Transducers:

- Turbine blade testing

- High temperature application

- Ball housing

- Special delay line / wedges

- Surface wave application

- Piston bond testing

- Rotary tube testing

- Coarse grain weld testing

- Array transducers

- Plate testing

- Propeller/ Compressor Blade Testing

PROBES

Ultrasonic Reference Blocks

A wide range of standard calibration blocks as per national & international specifications are available. Blocks are made in Steel & Aluminum. Special blocks to customer’s specification are also manufactured. Each block has serial number & test certificates are available.

REFERENCE BLOCKS

Ultrasonic Cables

We are supplying various types of cables required for connecting transducers to the Flaw Detector. Standard cables are supplied for normal usage. They are available in various connector types and in various lengths.

Ultrasonic Couplants

Ultrasonic waves cannot be transmitted properly through air. Hence use of couplant is always necessary to remove air bubble between a transducer & a test piece and to provide better acoustic coupling.

We are supplying various types of couplants for different applications.