Dye Penetrant Inspection

DPI CONSUMBLES :

We offer a complete range of Dye Penetrant Testing Consumables from PFINDER, Germany for Non Destructive Testing.

THINKING AHEAD SINCE 1884.

Technical competence, many years of experience and proximity to the customer – this is how PFINDER, as the inventor of cavity preservation in corrosion protection and in the field of penetrant and magnetic particle testing, offers its customers real added value.

PFINDER has combined decades of experience with the latest findings and developed a wide range of products.

PFINDER is known for Green NDT -Biodegradability, minimize carbon footprint (Global warming), Renewable /Re-cycle raw material. 360 Deg- Upside/Down Valve to use for 360 Deg Application.

What is penetrant testing?

Penetrant testing is a method of non-destructive material testing, in which surface material defects that are open to the surface can be revealed with the aid of so-called penetrants or test media. A distinction is made between dye penetrant inspection (also known as red-white testing), which uses red dye penetrants that are visible in daylight, and fluorescent penetrant inspection, which uses dyes that that shows defects under UV radiation with a yellow-green indication.

What are the advantages of penetrant testing?

- Fast and safe

- Location independent

- Suitable for individual parts testing, e.g. crack testing of a weld seam

- Suitable for large quantities

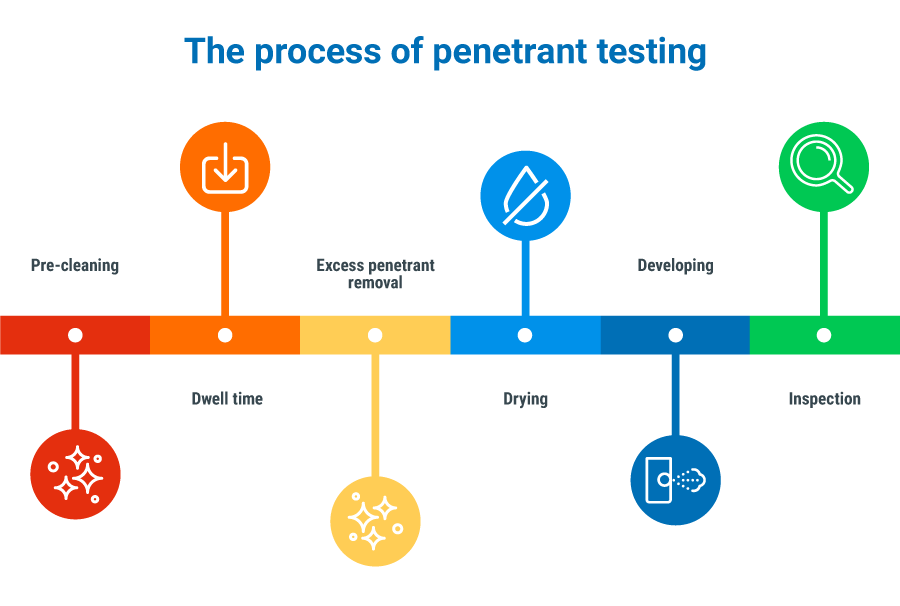

The penetrant testing process :

Step 1: Preliminary cleaning

The components which are to be tested must be cleaned superficially so that the penetrant can penetrate any existing defects. Residues on the surface of the material, such as scale, slag and rust etc. must be removed by brushing, sanding, grinding and, if necessary, by abrasive blasting. Care must be taken to ensure that the faults are not sealed by the cleaning process. The surface of the components must dry without residue.

Step 2: Penetrant process

The penetrant can be applied by spraying, rinsing or immersing the components which are to be tested. It is essential to ensure that the surface is thoroughly wetted. The penetration time (also called dwell time) is strongly dependent on the surface and ambient temperatures. The dwell time is longer at low temperatures. The test temperature can range from -20°C to +100°C.

Step 3: Excess penetrant removal

The penetrant is removed from the surface by rinsing or spraying with water or a solvent-based cleaner. Beware of washing out: The penetrant must not be washed out of the cracks.

Step 4: Drying procedure

After removing the excess penetrant with water or another cleaner, the surface should be dried with compressed air, a lint-free cloth or a suitable drying oven. If a cleaner is used which dries by evaporation due to highly volatile components, the drying process can be omitted.

Step 5: Developing

Immediately after drying, the developer is applied thinly and evenly. Aerosol spray cans or compressed air sprayers are particularly suitable. The developing time depends on the temperature of the component’s surface. The developing time is longer at low temperatures; at high temperatures it is shorter.

Step 6: Inspection

At the end of the development period, the test surface is scanned for indications, so-called inhomogeneities, in the developer layer. The assessment needs to be carried out under UV light when using fluorescent penetrants.

Initially, the indications appear as red lines or dots, which may continue to spread during the developing period in case of larger faults – this is called bleeding.

The indication only allows limited conclusions to be drawn about the width or diameter of the fault opening. No conclusions can be drawn about the depth of the fault opening.

Our products for non-destructive testing:

- Fluorescent penetrant testing

- Color contrast penetrant testing

- Cleaning agents and additives for penetrant testing

- Accessories for penetrant testing

PFINDER 860 RED PENETRANT

Type II / sensitivity level 2

Advantages:

- Nearly odourless.

- Bright, sharp indications with high contrast.

- Easy rinsability = low background.

PFINDER 871 DEVELOPER

Solvent based

Advantages:

- Aerosol spray can with minimized carbon footprint.

- Excellent developing properties.

- Quick drying.

PFINDER 895 MILD ODOUR CLEANER

Solvent based

Advantages:

- Mild odour.

- Powerful cleaner.

- All purpose use.

PFINDER 895 MILD ODOUR CLEANER

PFINDER 902 FLUORESCENT PENETRANT

Type I / Sensitivity level 2

Advantages:

- Readily biodegradable no waste water treatment required.

- Bright, sharp indications with high contrast.

- Easy rinsability = low background fluorescence.