Magnetic Particle Inspection

MPI CONSUMBLES :

We offer a complete range of Magnetic Particle Testing Consumables from PFINDER, Germany for Non Destructive Testing.

THINKING AHEAD SINCE 1884.

Technical competence, many years of experience and proximity to the customer – this is how PFINDER, as the inventor of cavity preservation in corrosion protection and in the field of penetrant and magnetic particle testing, offers its customers real added value.

PFINDER has combined decades of experience with the latest findings and developed a wide range of products.

PFINDER is known for Green NDT -Biodegradability, minimize carbon footprint (Global warming), Renewable /Re-cycle raw material. 360 Deg- Upside/Down Valve to use for 360 Deg Application.

What is magnetic particle testing?

Magnetic particle testing, also known as fluxing, is a surface testing method for non-destructive material testing. Defects in the material surface can be displayed by using a magnetic field.

What are the advantages of magnetic particle testing?

- Fast and reliable: Defects are made visible immediately

- Very sensitive: The finest surface defects are detected

- Flexible application: Almost completely independent of shape, size, surface roughness and condition of the component which is to be tested

- For stationary and mobile use

The magnetic particle testing process :

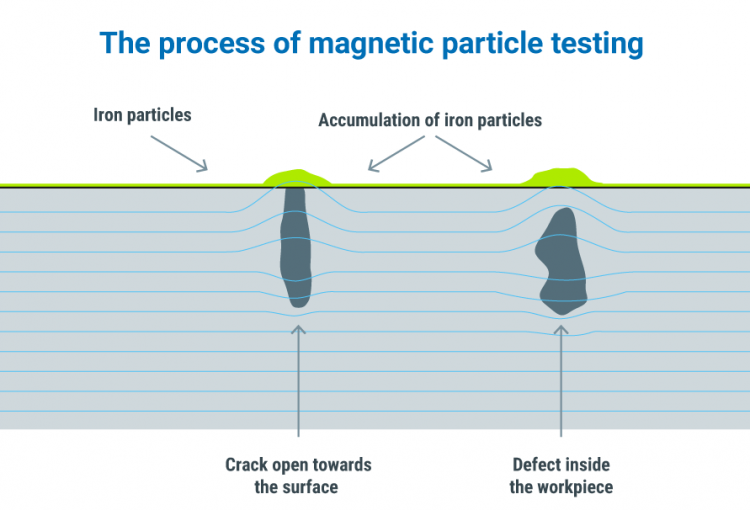

In this testing method, a ferromagnetic component is magnetized with the aid of generally artificially generated magnetic fields. During the magnetization process, the component is simultaneously rinsed with a testing medium for magnetic particle testing. The magnetic powder contained in the test medium accumulates at surface faults that are open to the surface. Due to the colour contrast between the magnetic powder and the component surface, surface faults are made visible and can be documented.

In magnetic particle testing, a ferromagnetic component is magnetized using mostly artificially generated magnetic fields. During the magnetization, the component is simultaneously rinsed with magnetic particles (usually suspended in a carrier liquid). The magnetic particles accumulate on surface defects that are open to the surface (due to the created magnetic leakage flux).

Due to the color contrast between magnetic powder and component surface, the surface defects become visible and can be documented. It is considered a highly reliable process in specialist circles. In the case of large workpieces where complete magnetization is not possible, only the part to be tested is magnetized.

Magnetic particle testing has two basic visualisation methods: It can be carried out in daylight or in the dark – using fluorescent magnetic particles.

Good to know: PFINDER cares about the environment. We are the first NDT manufacturer to create a carbon footprint of the most widely used consumables in order to minimize their environmental impact. Find out more about PFINDER’s GREEN NDT philosophy.

Our products for magnetic particle testing:

- Fluorescent Magnetic Particle Testing

- Magnetic Particle Suspensions

- Test oils and cleaners for magnetic particle testing

- Accessories for magnetic particle testing

PFINDER 280 WHITE CONTRAST PAINT

Quick-drying

Advantages:

- Free of silicone, sec. amines, nitrites/halogens

- Quick drying

- Low consumption due to high opacity

PFINDER 251 BLACK INK

Oil-based, ready to use

Advantages:

- Nearly odourless

- Excellent sharp, quick and stable indications

- Free of silicone, sec. amines, nitrites/halogens

PFINDER 150 FLUORESCENT MAGNETIC INK

Oil-based, ready to use

Advantages:

- Nearly odourless

- Excellent sharp, quick and stable indications with low background fluorescence

- Aerosol spray can with minimized carbon footprint

PFINDER 150 Fluorescent Magnetic Ink

ELECTROMAGNETIC INSPECTION YOKES

Types

- AC/DC Yoke 220 volts & 110 Volts

- Battery Operated DC yoke

Features

- Handy and Light Weight.

- Exceeds specific lift weight requirements.

- Safe for operators.

- Strong and rugged construction.

- Suitable to use in all type of industries

For more information, please contact us.

Click here

turgen@emirates.net.ae / sales@turgen.com

ELECTROMAGNETIC INSPECTION YOKES

Types

- AC/DC Yoke 220 volts & 110 Volts

- Battery Operated DC yoke

Features

- Handy and Light Weight.

- Exceeds specific lift weight requirements.

- Safe for operators.

- Strong and rugged construction.

- Suitable to use in all type of industries

Permanent magnetic yoke

Features

- Lifting Capacity: 18 kg. At 100 mm pole spacing

- Capable of Testing with both Dry and Wet method

For more information, please contact us.

Click here

turgen@emirates.net.ae / sales@turgen.com

ULTRAVIOLET LED LIGHT

We supply various type of UV LED Lights and Torches.

Features

- Compliance with all international standards and regulations

- Explosion proof certified per EU Directives

- Super light and handy design

- White light and UV light are easily switchable

- Power Supply: Battery or Mains

- 100% solid state circuit ensuring working steadily in strong magnetic field

- Safe and pure UV-A spectrum with no UV-B and UV-C

For more information, please contact us.